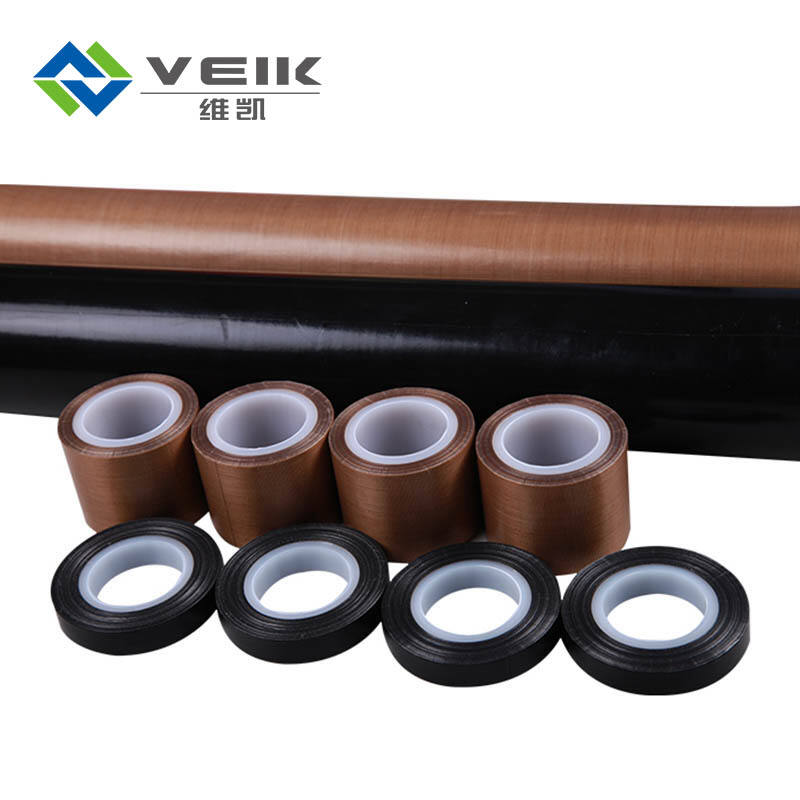

PTFE film adhesive tape is special type of lining material which may be used for convey the goods whose size are upto 18 inch approx. It is constructed from a very strong material that can handle chemicals, reduce friction and are resistant to high heat called Polytetrafluoroethylene (PTFE).

This tape is suitable for industrial work as it can sustain lot of pressure, thus stress. For sealing, for coating parts or to hold them in place It is frequently used by people in industries such as aerospace, automotive and electrical. FDA approval makes it food safe also.

You want to pack something or seal that, in this workshop place and factories this kind of tape are really important as well. This makes it ideal to use in heat sealing and vacuum packing which often expose the substance to very hot or moist conditions. Furthermore, the tape is strong enough to be water and chemical resistant as well So that makes it resist oils, acids or other dangerous things. Never leaves residual garbage, free from sticking to surfaces.

The Advantages of PTFE Film Adhesive Tape in High-Temperature

This tape is would be great for high heat jobs, like hot sealing or insulation work. It takes temperatures up to 260 degrees without breaking, which is a good thing when your out in the intense heat. The tape is excellent for when you need less friction on a job as well. It is easy to carry and holds your makeup for longer.

FEATURES The Inflexible States of America: How PTFE Film Adhesive Tape Handles the Strong Ones

This is the tape that has transformed things can be done in adverse conditions. It can withstand high temperatures, is resistant to chemicals and moisture and doesn't break down. Thanks to these special attributes, it is used quite extensively in a number of industrial applications.

To sum up, what I mean is that PTFE film adhesive tape has a wide range of applications in industry. It resists chemicals, reduces friction and handles high heat - which is why many workshops use it in their factories. It is this tape that is widely utilized across many industries; from aeronautical and automobile to aerospace, electric to food and beverage due its advantages. If you are not yet sure, but want to do more of this industrial work well couple / seal things together or even with high temperatures then the PTFE film adhesive tape is appropriate for your use!

3 PTFE film adhesive tapeThis is an amazing product with a variety of advantages in many industries. This tape, for its part is made from a chemically-resistant and highly durable material called PTFE (Polytetrafluoroethylene), that has very low friction coefficient but can withstand higher temperatures than almost any other known plastic.

Exploring How PTFE Film Adhesive Tape in Industries Are Infulfilling it's Potential

PTFE film adhesive tape is extremely versatile in its ability to withstand a wide range of industrial pressures and stressful conditions. It is used to seal joints, protect surfaces or fix components and it will prove itself useful for this project. Its use in aerospace, automotive and electrical industries is already widespread so its approval by the FDA for direct food contact means that it can be used in this sector too.

The value of PTFE film adhesive tape for packing and sealing processes is unmatched in workshops and factories. It is heat sealable and environmentally friendly, resistant to water (so will not warp) or chemicals so that it can provide a barrier against even the harshest elements. Efficient to apply and remove with the tape stripping easily thanks to its non-stick feature.

How Reliable is PTFE Film Adhesive Tape in High Temperature Environments

Its heat tolerance of up to 260°C (500°F) in addition to PTFE film adhesive tape makes it a top choice for hot tasks like insulation and gasketing. It also has a low friction coefficient, which is beneficial to applications that require very little sliding motion (low-friction) and wear properties, provide maintenance-free or long-term lubrication functionality.

PTFE Film Adhesive Tape: A Durable Option for Tough Situations

PTFE film adhesive tape improves extreme temperature resistance, chemical tolerance and robustness that is well-suited for industries challenging environments. This toughness enables it to be used for many industrial uses especially those with abusive conditions.

All in all, PTFE film adhesive tape is easily the most and largely used applicational product across industries widely known for its superior characteristics such as: Chemical Resistance, Low friction coefficient & Thermal stable exceptional asset. It is no wonder then that the robust tape serves a host of industries including aerospace, automotive, electrical and food & beverages. If you whether aim to optimize your industrial practices, reduce packaging and sealing process or deal with high-temperature challenges then PTFE film adhesive tape should find its spot at the peak of all answers!

Based the principles of taking root the lands and ptfe film adhesive tape, our products have been sold more than 60 countries in Europe, America, Oceania, Middle East, Asia Pacific, etc., which are widely used food processing industry, constructions industry, automobile industry, photovoltaic/solar energy industry, packaging industry, PTFE sunshades curtain and other fields.

Our company has been dedicated to the idea of building century Veik and building national brands. Our company puts ptfe film adhesive tape. Our products have that have passed SGS, the national glass fiber product inspection and supervision, as well as the national fireproof material inspection and supervision. Veik is a high-tech company in Jiangsu province.

In the future, VEIK will continues to keep the company's business philosophy that is better quality, ptfe film adhesive tape, professionalism, integrity. Be attentive to the needs of our customers constantly improves our services and offers superior customer services.

Our firm has been in business for a long time. We have ptfe film adhesive tape, 2 coating lines, as well as 5 PTFE production lines for architectural elastomers. We have imported over 10 sets vertical and horizontal drying equipment, Germany Karl Mayer high-speed automatic warping machine, and Dornier taper looms that have wide widths. Our annual production capacity is one million square meters.